Have you ever wondered why some materials are super strong while others break easily? Why can a metal bridge hold thousands of cars, but a plastic chair might crack if you sit on it the wrong way? The answer comes down to material strength and durability.

Different materials are used for different purposes based on their strength, flexibility, and resistance to damage. Understanding what makes a material strong can help in everything from designing buildings to choosing the right materials for DIY projects. Let’s break it down in a way that’s easy to understand.

What Does “Strong” Mean for a Material?

When we say something is strong, we usually mean it doesn’t break easily. But strength isn’t just about how much weight a material can hold. There are different types of strength that affect how a material behaves:

- Tensile Strength – How well a material resists being pulled apart (like a rope holding a heavy object).

- Compressive Strength – How much force a material can take when being squeezed (like a brick in a wall).

- Flexural Strength – How much bending a material can handle before breaking (like a plastic ruler).

- Impact Resistance – How well a material can absorb a sudden shock or hit (like a helmet protecting your head).

Depending on what a material is used for, it needs to have the right kind of strength for the job.

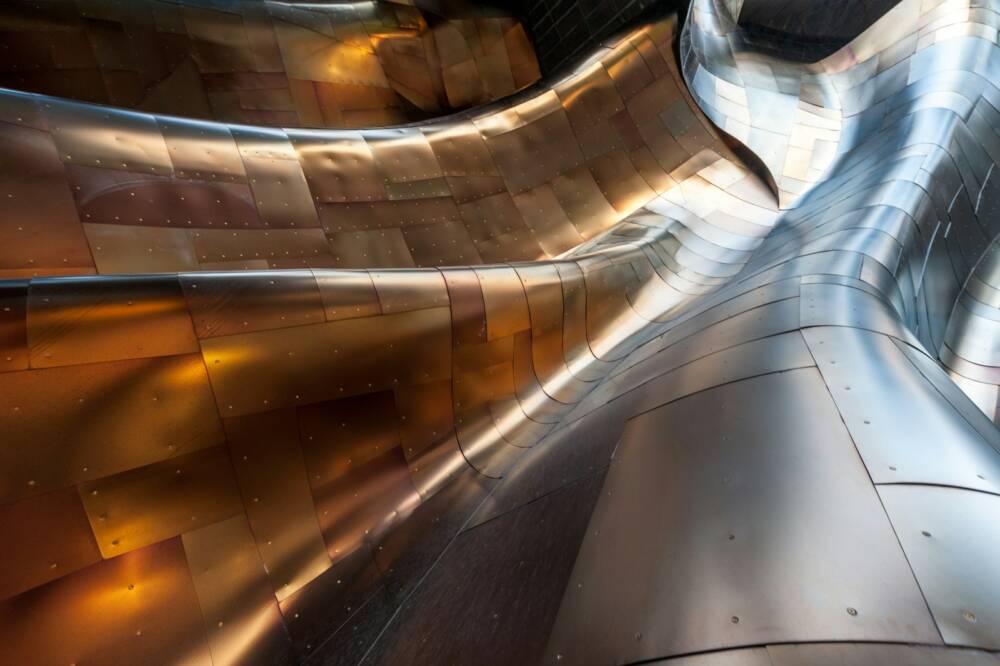

Metal: The King of Strength

Metals like steel, aluminum, and titanium are known for their durability. They are used in everything from skyscrapers to airplanes because they can handle heavy loads, high pressure, and extreme temperatures.

- Steel is one of the strongest materials and is used in bridges, buildings, and vehicles. It has high tensile and compressive strength.

- Aluminum is lightweight but still strong, making it perfect for airplanes and cars.

- Titanium is even stronger than steel but much lighter, which is why it’s used in aerospace and medical implants.

Metals can also be mixed with other elements to make them even stronger. This process is called alloying—for example, stainless steel is an alloy of iron, chromium, and nickel, making it resistant to rust.

Plastic: Not All Are Weak

When people think of plastic, they often imagine something weak, like a cheap water bottle. But not all plastics are the same. Some are incredibly strong and are even used in construction and protective gear.

- Polycarbonate is used in bulletproof glass and safety helmets because it has high impact resistance.

- Acrylic (Perspex) is used in clear barriers, signs, and displays because it’s lightweight and shatter-resistant.

- High-Density Polyethylene (HDPE) is used in pipes and storage tanks because it resists chemicals and pressure.

Plastics can be designed to be flexible like perspex or rigid like HDPE, depending on how they are made. That’s why you see them in so many different products, from food containers to industrial machines.

Wood: Nature’s Strongest Material

Wood has been used for thousands of years because it’s strong, lightweight, and easy to work with. Some types of wood are stronger than others, depending on how dense they are.

- Hardwoods like oak and maple are strong and durable, often used in flooring and furniture.

- Softwoods like pine are lighter and easier to cut, making them great for building houses.

- Engineered wood like plywood and MDF (medium-density fiberboard) combines multiple layers to make it stronger and more stable.

Even though wood isn’t as strong as metal, it’s great for construction because it can handle weight and absorbs shocks well. Plus, it looks good and is a renewable resource.

Glass and Ceramics: Strong but Fragile?

Glass and ceramics might seem weak because they break when dropped, but they have their own type of strength. They can resist heat, scratches, and chemical damage better than many other materials.

- Tempered glass is stronger than regular glass because it’s heated and cooled in a special way. It’s used in car windows and phone screens.

- Ceramic tiles are used in bathrooms and kitchens because they don’t absorb water and are tough against scratches.

- Porcelain and bone china are strong types of ceramics that can handle everyday use without cracking easily.

While these materials don’t bend or absorb shocks well, they are perfect for surfaces that need to be heat-resistant and long-lasting.

Composites: The Best of Both Worlds

Sometimes, the strongest materials come from mixing two or more materials together to get the best properties of each. These are called composites.

- Fiberglass (glass fibers mixed with plastic) is strong, lightweight, and used in boats, cars, and even sports equipment.

- Carbon fiber is lighter and stronger than steel, making it perfect for airplanes, race cars, and bicycles.

- Concrete (a mix of cement, sand, and gravel) gets even stronger when reinforced with steel bars.

Composites allow materials to be strong, lightweight, and flexible all at the same time, making them ideal for high-performance industries.

What Makes a Material Last Longer?

Even strong materials can wear down over time. What keeps them durable depends on a few factors:

- Weather Resistance – Some materials, like stainless steel and plastic, don’t rust or rot in rain and sun.

- Flexibility – Materials that can bend without breaking, like polycarbonate and aluminum, last longer in tough conditions.

- Coatings and Treatments – Paint, sealants, and protective layers help materials resist moisture, corrosion, and UV damage.

Choosing the right material for a job means thinking about what conditions it will face. That’s why outdoor furniture is often made from treated wood or aluminum, while indoor furniture is more likely to be made from softer materials like regular wood or fabric.

Why Does Material Strength Matter?

Whether you’re building a house, designing a product, or just picking the right phone case, knowing about material strength helps you make better choices. Strong materials keep buildings standing, protect us in cars and helmets, and make sure everyday products don’t break easily.

If you need a material that’s strong but lightweight, Perspex is a great choice. It’s used in signs, displays, and protective barriers because it’s durable and clear. Many businesses rely on Perspex cut to size for custom projects that need strength without the weight of glass.

The Right Material for the Right Job

There’s no single “strongest” material because different jobs require different strengths. A rope needs to resist pulling (tensile strength), while a brick needs to handle weight (compressive strength). A car needs materials that can bend in a crash, while a building needs materials that won’t bend too much.

Next time you use something, think about why it’s made from that specific material. Whether it’s metal, plastic, glass, or wood, every material has been chosen for a reason—and now, you know why!

MKTPlace is a leading digital and social media platform for traders and investors. MKTPlace offers premiere resources for trading and investing education, digital resources for personal finance, news about IoT, AI, Blockchain, Business, market analysis and education resources and guides.